Engineered for good performance in demanding industrial environments, the Professional Orange Weldin...

With the continuous development of manufacturing and infrastructure construction, metal cutting technology plays an increasingly important role in industrial production. Oxygen fuel cutting torches, acetylene cutting torches, and flame cutting torches are becoming essential tools for enterprises to improve production efficiency and ensure process quality.

Oxygen Fuel Cutting Torches: Balancing High Efficiency and Safety

Oxygen fuel cutting torches are one of the more commonly used cutting tools in modern industry. Their core advantages lie in their high cutting efficiency and stable operation. Oxygen fuel cutting achieves rapid cutting of metal materials by burning high-temperature oxygen and fuel gas. This method is not only suitable for common metals such as steel, but also widely used in construction, machinery manufacturing, and shipbuilding.

Technical professionals state that modern oxygen fuel cutting torches are equipped with a safety adjustment system that can regulate the flow rate of oxygen and fuel gas according to different metal thicknesses and cutting requirements, ensuring a stable flame and a smooth cut during the cutting process. This not only improves cutting efficiency but also reduces material waste and operational risks.

Breakthroughs have also been made in oxy-fuel cutting technology in terms of environmental protection and energy conservation. By improving combustion efficiency and reducing gas consumption, the equipment not only reduces energy use but also reduces exhaust emissions, providing enterprises with a more sustainable production solution. Industry experts believe that with the integration of intelligent control technology, oxy-fuel cutting torches will continue to play an important role in heavy industry and construction.

Acetylene Cutting Torch: Flexible and Reliable for Multiple Applications

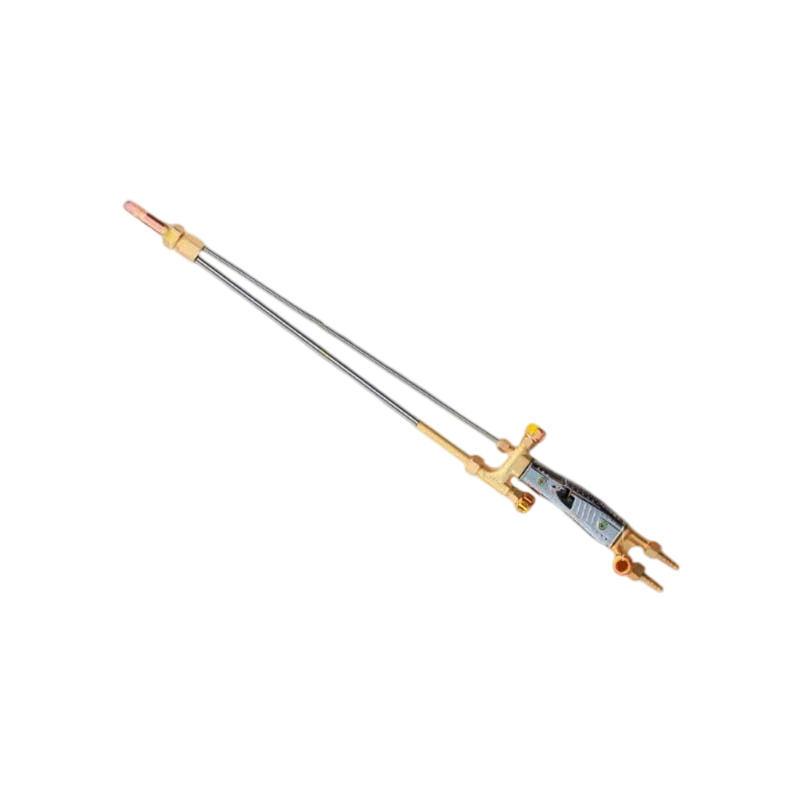

Acetylene cutting torches are favored by small and medium-sized enterprises and on-site construction teams due to their high-temperature flame and flexible operation. This type of cutting tool is not only suitable for steel cutting but also for pre-welding preparation and maintenance operations. Acetylene cutting is characterized by high flame temperature and moderate cutting speed, meeting diverse operational needs.

Acetylene cutting torches demonstrate advantages in practical applications such as ease of operation and strong controllability. Modern equipment is typically equipped with flow regulating valves and backfire prevention devices, enabling precise control of flame size and cutting depth while ensuring safety. For small and medium-sized manufacturing enterprises or construction sites, this convenience and safety are important considerations when selecting equipment.

Furthermore, the modular design of acetylene cutting torches facilitates disassembly and maintenance. Users can change nozzles or adjust the gas ratio according to different tasks, thus meeting the cutting needs of different metal materials and thicknesses. Industry analysts believe that with the increasing demand for on-site construction and maintenance services, the market potential for acetylene cutting torches remains significant.

Flame Cutting Torches: Combining Traditional Technology with Modern Applications

Flame cutting torches are tools based on the principle of oxy-fuel cutting, characterized by ease of operation and wide adaptability. Flame cutting is widely used in metal cutting tasks in building steel structures, disassembly and repair of mechanical equipment, and industrial production lines. Compared to traditional manual cutting, flame cutting torches can achieve more uniform kerfs and higher cutting efficiency.

Regarding safety and operational standards, modern flame cutting torch equipment effectively reduces operational risks by optimizing nozzle structure, incorporating backfire prevention devices, and implementing pressure regulation systems. Simultaneously, through digital control interfaces, operators can more intuitively adjust the flame pattern and cutting speed, achieving precise control over cutting quality. This technological upgrade makes flame cutting torches more adaptable to the needs of modern industrial production, building upon traditional cutting techniques.

It is worth noting that flame cutting torches exhibit high flexibility in various metal cutting tasks. Whether for portable cutting on-site or batch processing on a production line, the equipment provides stable flame output and uniform cutting results. This flexibility is a key reason for its continued popularity in the market.

Upgraded Cutting Technology Drives Industry Development

Intelligent and automated cutting equipment is becoming increasingly common, significantly improving cutting accuracy and production efficiency. By integrating data acquisition and monitoring systems, companies can track the cutting process in real time, adjust process parameters promptly, thereby optimizing production processes and reducing material waste.

Furthermore, the application scenarios for cutting torch equipment are constantly expanding. From traditional steel structures and mechanical parts processing to new energy equipment, transportation, and high-precision parts manufacturing, cutting torches are covering more industry sectors. The application of automation and intelligent technologies not only reduces operational difficulty but also improves cutting quality and efficiency, enabling the equipment to play a greater role in enterprise production.

Market Prospects and Development Trends

According to industry data analysis, the cutting torch equipment market will maintain steady growth in the coming years. Oxygen-fueled cutting torches continue to see growing demand in large-scale manufacturing and infrastructure construction. Acetylene cutting torches, with their flexibility and ease of operation, are highly competitive in small and medium-sized enterprises and on-site construction. Meanwhile, flame cutting torches, thanks to the stability of traditional processes and upgrades in modern technology, are steadily expanding in the industrial and maintenance markets.

Industry experts predict that cutting torch equipment will exhibit a diversified development trend. On the one hand, increased intelligence and automation levels will meet the demands of large-scale production and high-precision cutting; on the other hand, portable and easy-to-operate equipment will meet the practical needs of on-site construction and maintenance operations. Through the dual impetus of technological upgrades and market expansion, the cutting torch industry is expected to achieve sustained and steady development.

With continuous improvements in intelligent control, environmental protection technologies, and operational safety, the cutting torch equipment industry is developing towards greater efficiency, diversification, and safety, providing solid support for the manufacturing and construction industries.